In modern manufacturing, custom mechanical parts have become a crucial component of industrial upgrading and precision manufacturing. With the increasing prevalence of automated and intelligent production, more and more companies are choosing to design and produce customized mechanical parts tailored to their equipment structure, process requirements, and performance needs, in order to improve equipment efficiency and production stability. The use of customized parts not only optimizes the overall performance of mechanical systems but also promotes technological innovation and production model transformation within the manufacturing industry chain.

Definition and Core Value of Custom Mechanical Parts

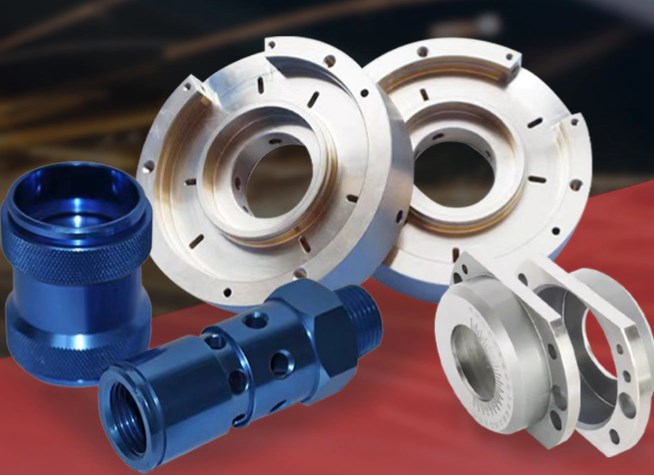

Custom mechanical parts are components that are individually designed and manufactured based on the structure, function, and operating environment of a specific piece of machinery or system. Unlike standard parts, the dimensions, tolerances, materials, surface treatment, and assembly methods of custom parts can be flexibly adjusted to meet customer needs.

This high degree of manufacturing flexibility enables mechanical equipment to achieve more precise structures and more targeted performance, thus meeting the operational requirements of diverse operating conditions. The greatest value of customized mechanical parts lies in their precise matching of function and structure, ensuring stable and efficient mechanical systems over extended periods of operation, reducing maintenance costs, and extending equipment life.

Innovations in materials and processes are driving the development of custom manufacturing.

In the manufacturing of custom mechanical parts, material selection and processing are key factors in determining quality and performance. With the continuous advancement of materials science, various types of metals, alloys, polymers, and composites are widely used in the manufacture of mechanical parts. High-strength alloys improve parts' wear resistance and fatigue resistance, while polymer engineering materials offer significant advantages in lightweighting and corrosion resistance.

Advances in manufacturing processes are also driving the development of custom parts. The integration of modern technologies such as CNC machining, precision casting, and additive manufacturing (3D printing) enables the rapid and high-precision production of complex mechanical components. Through automated inspection and digital control, manufacturers can achieve precise control over the production process, ensuring the consistency of size, shape, and surface quality for every part.

The Application Value of Custom Mechanical Parts in Industrial Production

Custom mechanical parts play an important role in numerous fields, including automated production, mechanical manufacturing, energy equipment, transportation, food packaging, and medical devices. Different industrial systems have varying requirements for component shape, strength, thermal stability, and precision. Customized design can achieve efficient coordination between equipment, reduce energy consumption, and improve production reliability.

In high-load, high-precision, high-temperature, or corrosive environments, standardized parts often cannot fully meet these requirements. However, customized mechanical parts can effectively improve equipment adaptability and service life through specialized structural design and surface treatment technologies, thereby bringing long-term economic and technical benefits to enterprises.

Quality Control and Inspection Standards for Custom Mechanical Parts

In high-precision manufacturing systems, quality control is a core component of custom mechanical parts production. Manufacturers typically implement a comprehensive inspection system to ensure component accuracy and consistency. Dimensional measurement, hardness testing, surface roughness testing, and non-destructive testing are widely used on-site to ensure that every part meets design standards and customer requirements.

Concurrently, with the deepening of international cooperation, quality system certification requirements for mechanical parts are continuously increasing in different countries and regions. Customized parts that meet international standards such as ISO and CE not only enhance a company's market competitiveness but also provide a guarantee for the promotion of mechanical equipment in the global market.

The Future of Sustainable Manufacturing and Green Materials

As the global manufacturing industry moves toward sustainable development, custom mechanical parts are also undergoing a green manufacturing transformation. Energy conservation and emission reduction, material recycling, and process optimization have become key keywords for industry development.

By selecting recyclable materials, low-energy processing technologies, and environmentally friendly coatings, manufacturers not only reduce carbon emissions during production but also achieve efficient resource utilization. With increasingly stringent environmental regulations, green manufacturing is gradually becoming a key competitive advantage in the custom mechanical parts industry.

In the future industrial system, custom mechanical parts will continue to play a key role in equipment upgrades and intelligent manufacturing. Customization not only represents personalized design needs but also reflects the comprehensive strength of industrial technology and innovation capabilities.

With the deep integration of advanced materials, digital design, and intelligent manufacturing, custom mechanical parts will drive technological progress across various industries with higher precision, better performance, and greater adaptability. Whether in traditional manufacturing or emerging industries, customized mechanical parts will become a vital bridge connecting design concepts with practical applications, helping the global manufacturing industry move towards a higher level of quality development.

English

English русский

русский