Amid the global manufacturing transformation and upgrade, CNC Machinery Parts Producers have become a key force driving the development of intelligent and precision industries. With the continuous advancement of CNC machining technology, mechanical parts production is gradually evolving from traditional processes to digitalization and automation, meeting the stringent demands for high-precision components in sectors such as aerospace, automotive, medical devices, and precision electronics. The quality of CNC parts not only impacts the performance and lifespan of the final product but also reflects a manufacturer's technical strength and industry standing.

The Professional Value of CNC Parts Production

CNC Machinery Parts Producers play a vital role in the industry chain. Using CNC machine tools to perform precise cutting, milling, turning, and drilling processes, they produce parts with high dimensional accuracy, excellent surface finish, and robust stability. Compared to traditional machining methods, CNC technology enables the manufacture of complex components in shorter production cycles, significantly improving production efficiency and consistency. For industry customers, this not only reduces costs but also provides a crucial guarantee for product performance.

Technology-Driven Intelligent Manufacturing

Amidst the backdrop of intelligent manufacturing, CNC machinery parts manufacturers are continuously introducing advanced processing equipment and automation systems. High-precision five-axis CNC machine tools make it possible to process complex curved parts. Combined with automated loading and unloading systems and robotic arms, production efficiency is significantly improved. The application of intelligent monitoring and big data analysis technologies enables real-time tracking and adjustment of parameters during the production process, ensuring that every component meets design standards, thereby promoting intelligent and transparent production lines.

Diversified Innovation in Materials and Processes

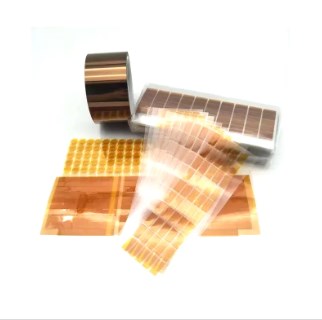

CNC parts are widely used, and different industries have varying requirements for materials and performance. CNC machinery parts manufacturers typically process a variety of materials, including stainless steel, aluminum alloy, titanium alloy, copper, and engineering plastics, based on customer requirements. By continuously optimizing tool paths, cooling methods, and cutting parameters, they can ensure precision while maximizing part life. In some high-end manufacturing fields, combining surface treatment processes such as anodizing, electroplating, spray painting, and polishing has become an important means of enhancing the overall performance of parts.

Trends in Customized and Flexible Production

Customer demands in the modern manufacturing industry are gradually shifting from standardized parts to customized and flexible production. CNC Machinery Parts Producers utilize modular production lines and advanced software systems to enable rapid transitions from design to manufacturing. They can flexibly handle both small-batch, diversified parts production and large-volume, highly consistent machining. This flexible manufacturing model is key to enhancing companies' market competitiveness and meeting diverse needs.

Challenges and Opportunities of Sustainable Development

Amid the global advocacy of green manufacturing and a low-carbon economy, CNC Machinery Parts Producers face new challenges. Reducing energy consumption and material waste while maintaining production efficiency has become a key focus in the industry. Some leading companies are adopting recycled materials, optimizing cutting fluid usage, and implementing environmentally friendly processes to achieve sustainable production. This not only helps companies fulfill their social responsibilities but also becomes a key component in earning customer trust and enhancing brand value.

Future Development Prospects

In the future, CNC Machinery Parts Producers will further advance towards digitalization, networking, and intelligence, fueled by smart manufacturing and the Industrial Internet. With the deep integration of artificial intelligence, the Internet of Things, and big data technologies, component production will become more precise and efficient. By establishing digital twin systems, companies can simulate manufacturing processes in a virtual environment, significantly shortening R&D and trial production cycles.

English

English русский

русский